John Economaki recently pointed out that Chris has the exact voice of Tom Brokaw. Click the hyperlinks to see for yourself. Watching his videos are never the same anymore. I also see that Mr. Schwarz is coming to Alpharetta in March to teach some classes. That might be fun.

Anyhow, yesterday's blog entry was titled "A Dovetail a Day-Hurray." Not the cleverest title, I know. Apparently he had written a little article in Popular Woodworking a couple of months ago about getting really good at dovetailing by knocking out one every day for a month. His blog links to the article which I think raises a really good point. I'll quote:

"So many times we learn woodworking on the fly as we build something. We get our skills just good enough to accomplish that project and then we move on. It's rare to get out a board and just saw it. Or plane it. Or mortise it with our router."

True, true. A reader took him up on this and the results are pretty good. By limiting yourself to only one at a time you have time to scrutinize your previous mistakes and try to do better the next time.

So that's my plan: 30 joints. I have some poplar ("the other softwood") floating around that I think will be pretty good for it. Poplar is pretty soft and can be unforgiving to the heavy-handed. I'm also going to add speed to the mix too. My goal--inspired by Konrad Sauer--is to be very efficient while increasing accuracy.

Here are the rules:

-the stock will be prepped and ready to go

-tools will be laid out and ready to go

-no pre-layout is allowed

-all marking and measuring gauges must be zeroed out...no presetting

-Start=touch tools

-Finish=plane the pieces flush and put down the plane

Cell phone kept time.

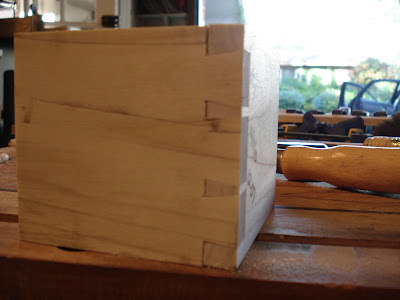

Every joint will have 3 tails, 2 pins and 2 half-pins. Here are the results of day one:

Some observations:

-I think I should throw away my dovetail angle guides. The slope of my tails here were defined by eye and cut freehand. I think that they are pretty darn consistent.

-It would be worth the time to be a little more mindful of my depth of cut. I'm shooting through my scribe line just about every time. Usually I'm not too bad with this but I neglected it here because of the clock...not smart.

-The jointer plane was used to finish out the joint. There was no need for that big thing...next time I'm using the smoother.

As the picture says, I finished this one in 12 minutes and 7 seconds. That's not really too bad but the quality needs to come way up. Joinery maestro Rob Cosman (another Canadian, by the way) has it down to under 4 minutes and Frank Klausz has it closer to 3.